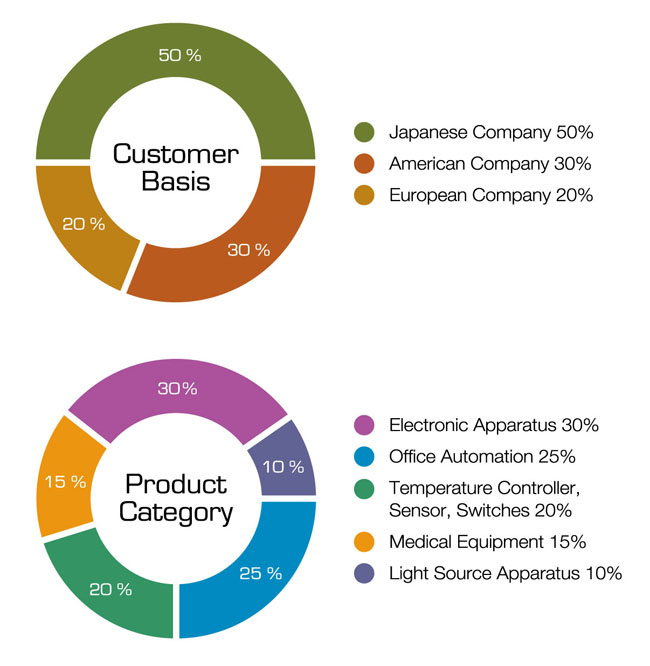

Introduction Sun Ah Electric Factory Limited has been established in Hong Kong with precise metal stamping business since 1978. Our products includes all sorts of metal stamping parts, deep draw parts, metal cases, aluminum heat sinks, terminals, and insulation fiber plates. Production arts range from conventional metal stamping, progressive stamping, deep drawing, welding, spot welding, tapping, polishing, and assembly. Our production plant is located in Gualan, Shenzhen with more than 45,000 sq. feet to back up our production capability. With more than 30 years of solid experience, we are confident to provide comprehensive services and tangible values to our customers other than just offering competitive prices and quality products. To support our claims, we have an aspirated company policy to keep us on the right track for our business. " Quality Priority, Customer Satisfaction, On-Time delivery, Protection on Environment, Health and Safe Environment " is our company's policy. Through constantly review our policy's performance, we are striving to serve better of our customers' needs. Apart from manufacturing facilities, we have a sound engineering background including teams of projects designers and engineers who keep on to pursue better technical and quality performance. To maintain stable and upgrading employees is invaluable assets for our company to keep on better quality performance. By providing ongoing job trainings and improving working environment, We , Sun Ah, all work together to strive for better future of our company. In face of vigorous competition, we are striving to increase our competitiveness by acquiring more range of capacity of machinery. During these years, we have equipped with 30% more of machinery and recruited with 30% more employees to cope with our increasing production capacity. Keep on acquiring more with higher precision and efficiency of machinery, and expanding production ranges are our coming visions of company development. Striving to offer our customers with best services for better quality, higher efficiency and lower prices is our long-term company goal.  |

|